Understanding the Diesel Exhaust System

Ever wondered about that maze of pipes and components hanging under your diesel truck? It's not just there for show! It's a vital system designed to keep our air clean and your engine running efficiently. The diesel exhaust system can seem complicated, but breaking it down makes it easier to understand its purpose and how it functions.

Many diesel vehicle owners find themselves scratching their heads when faced with dashboard warnings or performance issues related to their exhaust system. Deciphering the jargon, understanding the various components, and knowing how to properly maintain the system can feel overwhelming, leading to costly repairs and unnecessary stress.

This article aims to demystify the diesel exhaust system. We'll explore its key components, explain how it works to reduce harmful emissions, and offer practical advice on maintenance and troubleshooting. By the end, you'll have a solid understanding of this critical system and be better equipped to keep your diesel engine running smoothly and cleanly.

In essence, we'll be dissecting the Diesel Exhaust System (DES), exploring components like the Diesel Particulate Filter (DPF), Selective Catalytic Reduction (SCR), Diesel Oxidation Catalyst (DOC), and the vital role of Diesel Exhaust Fluid (DEF). We'll touch upon maintenance practices, common problems, and potential solutions, empowering you to navigate the world of diesel emissions control with greater confidence.

The Role of the Diesel Particulate Filter (DPF)

I remember the first time I heard about a DPF. I was talking to a mechanic about my old truck, and he mentioned needing to "regenerate" it. I had no clue what he was talking about! After a little research, I learned that the DPF is like a sophisticated filter that traps soot and particulate matter from the exhaust stream. This prevents those nasty black clouds of smoke we used to associate with diesel engines from polluting the air. The "regeneration" he mentioned is the process of burning off that accumulated soot to clean the filter. If this process doesn't happen properly, it can lead to a clogged DPF, reduced engine performance, and eventually, a costly replacement. This personal experience highlights the importance of understanding your DPF and how to ensure it regenerates effectively. Driving habits, fuel quality, and regular maintenance all play a crucial role in keeping this vital component functioning optimally. The DPF is a crucial component in modern diesel vehicles, designed to capture particulate matter, or soot, from the exhaust gases. It's essentially a filter that traps these particles to prevent them from being released into the atmosphere. Over time, the DPF becomes full and requires a process called regeneration to clean itself. Regeneration involves burning off the accumulated soot at high temperatures, turning it into ash. There are two main types of regeneration: active and passive. Active regeneration is triggered by the engine control unit (ECU) when the DPF reaches a certain level of soot accumulation. The ECU injects extra fuel into the exhaust stream, raising the temperature and initiating the burn-off process. Passive regeneration occurs naturally during normal driving conditions when the exhaust temperature is high enough. Factors like driving speed, engine load, and ambient temperature can affect the frequency of regeneration. If regeneration doesn't occur properly, the DPF can become clogged, leading to reduced engine performance, increased fuel consumption, and potential damage to the engine. Regular maintenance and proper driving habits can help ensure the DPF functions optimally and prolong its lifespan.

Understanding Selective Catalytic Reduction (SCR)

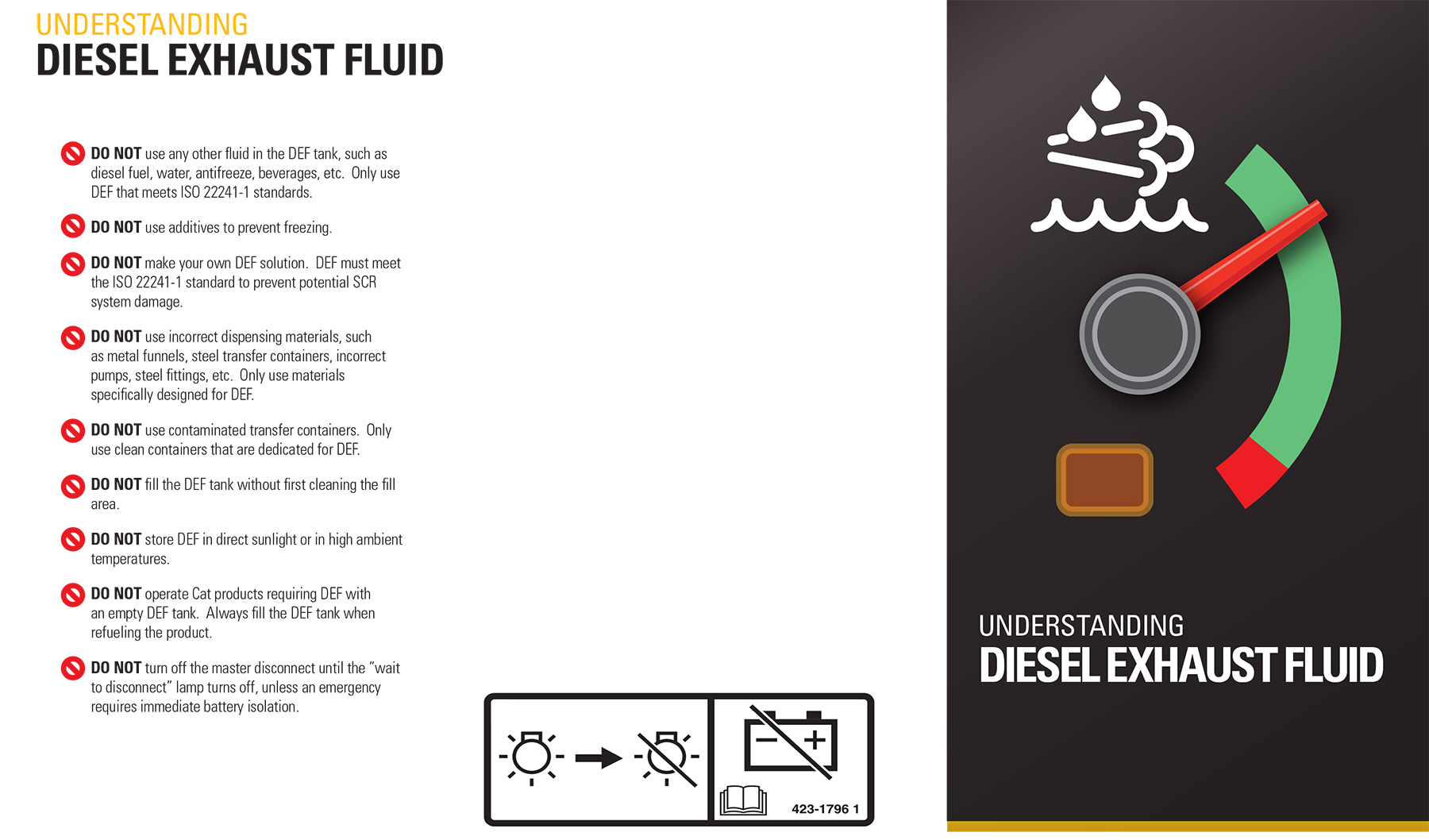

Selective Catalytic Reduction, or SCR, is a technology used to reduce nitrogen oxides (NOx) emissions from diesel engines. NOx are harmful pollutants that contribute to smog and acid rain. The SCR system works by injecting Diesel Exhaust Fluid (DEF), a solution of urea and water, into the exhaust stream. The DEF reacts with the NOx in the presence of a catalyst, converting them into harmless nitrogen and water. The SCR system consists of several key components, including a DEF tank, a DEF injector, a catalyst, and a control unit. The DEF tank stores the DEF solution, which is typically a 32.5% urea solution. The DEF injector sprays the DEF into the exhaust stream, where it mixes with the NOx. The catalyst is a specially coated material that promotes the chemical reaction between the DEF and the NOx. The control unit monitors the system and adjusts the DEF injection rate based on engine operating conditions. Proper maintenance of the SCR system is essential to ensure its effectiveness. This includes regularly checking the DEF level and adding DEF as needed. It's also important to use high-quality DEF that meets the required specifications. Contaminated or diluted DEF can damage the SCR system and reduce its performance. Furthermore, it's crucial to address any issues with the SCR system promptly. Symptoms of SCR system problems can include reduced engine performance, increased fuel consumption, and warning lights on the dashboard. Ignoring these symptoms can lead to more serious damage and costly repairs. Understanding the SCR system and its maintenance requirements can help diesel vehicle owners keep their engines running cleanly and efficiently.

The History and Myths Surrounding Diesel Exhaust Systems

The evolution of the diesel exhaust system is a fascinating journey driven by increasingly stringent emissions regulations. Early diesel engines were notorious for their smoky exhaust, a far cry from the relatively clean vehicles we see today. The development of technologies like the DPF and SCR was a direct response to the growing awareness of the environmental impact of diesel emissions. Initially, there was resistance to these technologies, with some mechanics and drivers viewing them as unnecessary complications that added to the cost of maintenance. One common myth is that removing the DPF or SCR system will improve engine performance and fuel economy. While this might seem appealing in the short term, it's not only illegal but also harmful to the environment. Moreover, it can lead to serious engine damage and void warranties. Another myth is that all DEF is the same. In reality, the quality of DEF can vary significantly, and using substandard DEF can damage the SCR system. It's crucial to use DEF that meets the required specifications and is from a reputable supplier. Over time, as awareness of the benefits of these technologies has grown, and as manufacturers have refined their designs, the perception of diesel exhaust systems has improved. Today, they are recognized as essential components for reducing pollution and protecting the environment. Understanding the history and debunking the myths surrounding diesel exhaust systems is crucial for making informed decisions about their maintenance and operation. It also helps to appreciate the significant advancements that have been made in diesel engine technology to reduce emissions and improve air quality. The narrative surrounding diesel exhaust systems has evolved from skepticism to recognition of their vital role in environmental protection.

Hidden Secrets of the Diesel Exhaust System

One of the lesser-known aspects of the diesel exhaust system is its ability to adapt to different driving conditions. The engine control unit (ECU) constantly monitors various parameters, such as exhaust temperature, engine load, and vehicle speed, and adjusts the operation of the exhaust system accordingly. For example, during prolonged periods of idling, the ECU may initiate a forced regeneration of the DPF to prevent it from becoming clogged. Another hidden secret is the intricate network of sensors and actuators that work together to control the exhaust system. These sensors provide real-time feedback to the ECU, allowing it to make precise adjustments to the DEF injection rate, the EGR valve position, and other parameters. The actuators, such as the DEF injector and the EGR valve, respond to the ECU's commands, ensuring that the exhaust system operates optimally. Furthermore, the diesel exhaust system is not just about reducing emissions; it also plays a role in improving engine performance and fuel economy. By optimizing the combustion process and reducing backpressure, the exhaust system can help to increase engine power and efficiency. However, the complexity of the diesel exhaust system also means that there are many potential points of failure. A malfunctioning sensor, a clogged DPF, or a faulty DEF injector can all lead to reduced engine performance, increased emissions, and potential damage to the engine. Therefore, it's essential to have the exhaust system regularly inspected and maintained by a qualified technician. By understanding the hidden secrets of the diesel exhaust system, diesel vehicle owners can better appreciate its importance and take steps to ensure its proper operation.

Recommendations for Maintaining Your Diesel Exhaust System

Preventive maintenance is key to keeping your diesel exhaust system functioning optimally and avoiding costly repairs. One of the most important recommendations is to use high-quality fuel and DEF that meet the required specifications. Contaminated or diluted fuel and DEF can damage the exhaust system components and reduce their performance. Another recommendation is to follow the manufacturer's recommended maintenance schedule. This typically includes regular inspections of the DPF, SCR system, and other components. It's also important to check the DEF level regularly and add DEF as needed. In addition to regular maintenance, it's also important to be aware of the symptoms of exhaust system problems. These symptoms can include reduced engine performance, increased fuel consumption, warning lights on the dashboard, and unusual exhaust smells. If you notice any of these symptoms, it's important to have the exhaust system inspected by a qualified technician as soon as possible. Furthermore, it's crucial to drive your vehicle in a way that promotes proper regeneration of the DPF. This typically involves driving at highway speeds for a certain period of time each week. This allows the exhaust temperature to reach the level required for passive regeneration. Finally, it's important to avoid modifying or tampering with the exhaust system. Removing the DPF or SCR system, or using aftermarket parts that are not approved by the manufacturer, can lead to serious engine damage and void warranties. By following these recommendations, diesel vehicle owners can keep their exhaust systems functioning properly and avoid costly repairs.

Understanding the EGR System and Its Role

The Exhaust Gas Recirculation (EGR) system is another crucial component of the diesel exhaust system, working in conjunction with the DPF and SCR to reduce emissions. The EGR system recirculates a portion of the exhaust gas back into the engine's intake manifold, diluting the incoming air and lowering the combustion temperature. This, in turn, reduces the formation of nitrogen oxides (NOx), which are harmful pollutants. The EGR system typically consists of an EGR valve, an EGR cooler, and a control unit. The EGR valve controls the amount of exhaust gas that is recirculated. The EGR cooler cools the exhaust gas before it is recirculated, which further reduces the combustion temperature. The control unit monitors the system and adjusts the EGR valve position based on engine operating conditions. Proper maintenance of the EGR system is essential to ensure its effectiveness. Over time, the EGR valve and cooler can become clogged with soot and carbon deposits, reducing their performance. Therefore, it's important to have the EGR system regularly inspected and cleaned. Symptoms of EGR system problems can include reduced engine performance, increased fuel consumption, rough idling, and warning lights on the dashboard. Ignoring these symptoms can lead to more serious damage to the engine. Understanding the EGR system and its maintenance requirements can help diesel vehicle owners keep their engines running cleanly and efficiently. The integration of the EGR system with the DPF and SCR is a testament to the complexity and sophistication of modern diesel exhaust systems, all designed to minimize the environmental impact of diesel engines.

Tips for Troubleshooting Common Diesel Exhaust System Issues

When faced with a potential issue with your diesel exhaust system, a systematic approach to troubleshooting can save you time and money. Start by checking the basics: Is the DEF tank full? Are there any visible leaks or damage to the exhaust system components? Next, use a scan tool to check for diagnostic trouble codes (DTCs). These codes can provide valuable clues about the nature of the problem. However, it's important to understand that DTCs are not always definitive, and further investigation may be required. For example, a DTC indicating a DPF issue could be caused by a clogged DPF, a faulty sensor, or a problem with the regeneration system. When troubleshooting DPF issues, it's important to consider your driving habits. Are you driving primarily short distances at low speeds? This can prevent the DPF from regenerating properly. Try driving at highway speeds for a while to see if the DPF regenerates. If that doesn't work, you may need to have the DPF cleaned or replaced. When troubleshooting SCR system issues, check the quality of the DEF. Using contaminated or diluted DEF can damage the SCR system. You can use a DEF refractometer to check the DEF concentration. Also, inspect the DEF injector for clogs or leaks. If you're not comfortable troubleshooting exhaust system issues yourself, it's best to take your vehicle to a qualified technician. They have the tools and expertise to diagnose and repair the problem correctly. Remember, addressing exhaust system issues promptly can prevent more serious damage and costly repairs down the road. A proactive approach to maintenance and troubleshooting is always the best strategy.

The Impact of Fuel Quality on Your Diesel Exhaust System

The quality of fuel you use has a direct and significant impact on the performance and longevity of your diesel exhaust system. Low-quality fuel can contain contaminants that clog the DPF, damage the SCR system, and reduce the effectiveness of the EGR system. These contaminants can include sulfur, water, and sediment. Sulfur, in particular, can poison the catalysts in the SCR system, reducing their ability to convert NOx into harmless nitrogen and water. Water can cause corrosion and damage to fuel system components, while sediment can clog fuel filters and injectors. Using high-quality fuel from a reputable supplier is essential to protect your diesel exhaust system. Look for fuel that meets the ASTM D975 standard for diesel fuel. This standard specifies the requirements for diesel fuel quality, including limits on sulfur content, water content, and sediment content. In addition to fuel quality, the type of fuel you use can also impact your exhaust system. Biodiesel, for example, can have different properties than conventional diesel fuel, and it may not be compatible with all diesel engines. Check your vehicle's owner's manual to see if it is approved for use with biodiesel. Furthermore, consider using fuel additives to improve fuel quality and protect your exhaust system. Fuel additives can help to remove water and sediment from fuel, improve fuel lubricity, and prevent fuel gelling in cold weather. By paying attention to fuel quality, you can help to keep your diesel exhaust system functioning properly and avoid costly repairs. A little extra care in selecting your fuel can go a long way in protecting your investment.

Fun Facts About Diesel Exhaust Systems

Did you know that the technology used in diesel exhaust systems has its roots in the chemical industry? The catalytic converters used in SCR systems are based on technology originally developed to reduce emissions from industrial processes. Another fun fact is that the amount of DEF used by a diesel vehicle is relatively small compared to the amount of fuel it consumes. Typically, a diesel vehicle will use about 2-5% DEF relative to the amount of diesel fuel it consumes. This means that a vehicle that gets 20 miles per gallon will use about 1 gallon of DEF for every 400-1000 miles driven. Also, the DPF can withstand incredibly high temperatures during regeneration. The temperature inside the DPF can reach up to 1100 degrees Fahrenheit during the regeneration process. That's hot enough to melt some metals! The development of diesel exhaust systems has led to a significant reduction in diesel emissions. Modern diesel engines are significantly cleaner than older diesel engines, thanks to technologies like the DPF, SCR, and EGR. Furthermore, diesel exhaust systems are constantly evolving. Engineers are continuously developing new and improved technologies to further reduce emissions and improve fuel efficiency. So, the next time you see a diesel vehicle on the road, remember that it's equipped with a sophisticated system designed to protect the environment. These fun facts highlight the ingenuity and innovation that have gone into the development of diesel exhaust systems. They also underscore the importance of these systems in reducing pollution and protecting the environment.

How to Improve Your Diesel Exhaust System

While modern diesel exhaust systems are designed to be efficient and reliable, there are steps you can take to further improve their performance and longevity. One approach is to optimize your driving habits. Avoid short trips and excessive idling, as these can prevent the DPF from regenerating properly. Instead, try to drive at highway speeds for a certain period of time each week to allow the DPF to regenerate passively. Another way to improve your diesel exhaust system is to use high-quality fuel and DEF. Contaminated or diluted fuel and DEF can damage the exhaust system components and reduce their performance. Look for fuel and DEF that meet the required specifications and are from a reputable supplier. Consider using fuel additives to improve fuel quality and protect your exhaust system. Fuel additives can help to remove water and sediment from fuel, improve fuel lubricity, and prevent fuel gelling in cold weather. You can also install aftermarket parts to improve the performance of your diesel exhaust system. For example, you can install a performance exhaust system to reduce backpressure and improve engine power. However, it's important to choose aftermarket parts that are approved by the manufacturer and are compatible with your vehicle. Finally, it's crucial to have your diesel exhaust system regularly inspected and maintained by a qualified technician. They can identify and address any potential problems before they become serious. By taking these steps, you can help to keep your diesel exhaust system functioning optimally and avoid costly repairs. Remember, a well-maintained exhaust system not only reduces emissions but also improves engine performance and fuel efficiency.

What If Your Diesel Exhaust System Fails?

A failing diesel exhaust system can lead to a cascade of problems, impacting everything from engine performance to fuel economy and even compliance with emissions regulations. One of the most common consequences is reduced engine power. A clogged DPF, for example, can restrict exhaust flow, reducing engine power and acceleration. Increased fuel consumption is another likely outcome. A malfunctioning SCR system can result in higher NOx emissions, which can trigger the engine control unit (ECU) to reduce fuel efficiency in an attempt to compensate. Failure to comply with emissions regulations can result in fines and penalties. Many jurisdictions require diesel vehicles to pass emissions tests, and a failing exhaust system can cause a vehicle to fail these tests. More seriously, a failing exhaust system can cause damage to other engine components. For example, a clogged DPF can cause excessive backpressure, which can damage the turbocharger and other engine parts. Safety can also be compromised. Leaks in the exhaust system can allow harmful gases, such as carbon monoxide, to enter the vehicle cabin. Furthermore, ignoring exhaust system problems can lead to more costly repairs down the road. A small problem with the SCR system, for example, can eventually lead to the failure of the entire system. Therefore, it's crucial to address any issues with your diesel exhaust system promptly. Ignoring the problem will only make it worse and more costly to repair. Regular maintenance and prompt repairs can help to prevent these problems and keep your diesel engine running smoothly and cleanly. Early detection and intervention are key to minimizing the impact of a failing diesel exhaust system.

A Listicle of Common Diesel Exhaust System Problems

Let's break down some common diesel exhaust system woes into an easy-to-digest listicle: 1. Clogged DPF: This is a frequent issue, often caused by short trips and infrequent regeneration. Symptoms include reduced engine power and a DPF warning light.

2. Faulty DEF Injector: A malfunctioning DEF injector can disrupt the SCR system, leading to increased NOx emissions and potential engine damage.

3. SCR System Failure: The SCR system can fail due to contaminated DEF, faulty sensors, or catalyst degradation.

4. EGR Valve Problems: A clogged or malfunctioning EGR valve can cause rough idling, reduced engine power, and increased emissions.

5. Exhaust Leaks: Exhaust leaks can lead to reduced engine performance, increased noise, and potential safety hazards.

6. Sensor Failures: The diesel exhaust system relies on a network of sensors to monitor its operation. A faulty sensor can disrupt the system and trigger warning lights.

7. Turbocharger Issues: The turbocharger is an integral part of the diesel engine, and its performance is closely linked to the exhaust system. Turbocharger problems can affect exhaust flow and emissions.

8. Fuel Injector Problems: Faulty fuel injectors can lead to incomplete combustion, which can increase particulate matter emissions and clog the DPF.

9. Low-Quality Fuel: Using low-quality fuel can damage the entire fuel and exhaust system, leading to a variety of problems.

10. Neglecting Maintenance: Failing to follow the manufacturer's recommended maintenance schedule can lead to a variety of exhaust system problems. This list highlights the importance of regular maintenance and prompt repairs to keep your diesel exhaust system functioning properly. Addressing these issues early can prevent more serious damage and costly repairs.

Question and Answer about Understanding the Diesel Exhaust System

Q: What is the main purpose of a diesel exhaust system?

A: The primary goal of a diesel exhaust system is to reduce harmful emissions from diesel engines, including particulate matter (soot) and nitrogen oxides (NOx), to meet increasingly stringent environmental regulations.

Q: What are the key components of a modern diesel exhaust system?

A: The main components typically include a Diesel Particulate Filter (DPF), Selective Catalytic Reduction (SCR) system with Diesel Exhaust Fluid (DEF), Diesel Oxidation Catalyst (DOC), and an Exhaust Gas Recirculation (EGR) system.

Q: How does the DPF work to reduce emissions?

A: The DPF traps particulate matter (soot) from the exhaust stream. Over time, this soot is burned off in a process called regeneration, either passively during normal driving or actively through increased exhaust temperatures.

Q: What is DEF and why is it important for the SCR system?

A: DEF (Diesel Exhaust Fluid) is a solution of urea and water that is injected into the exhaust stream in the SCR system. It reacts with nitrogen oxides (NOx) in the presence of a catalyst, converting them into harmless nitrogen and water.

Conclusion of Understanding the Diesel Exhaust System

Understanding the diesel exhaust system is no longer just for mechanics; it's essential knowledge for any diesel vehicle owner. From the DPF's soot-trapping prowess to the SCR's NOx-busting capabilities, each component plays a crucial role in keeping our air clean and our engines running efficiently. By staying informed about maintenance practices, recognizing potential problems, and choosing quality fuel and DEF, you can extend the life of your exhaust system and contribute to a healthier environment. The diesel exhaust system, once a source of smoky emissions, has evolved into a sophisticated piece of engineering that is vital for sustainable transportation. By embracing this understanding, we can ensure that diesel engines continue to play a role in our world while minimizing their environmental impact.